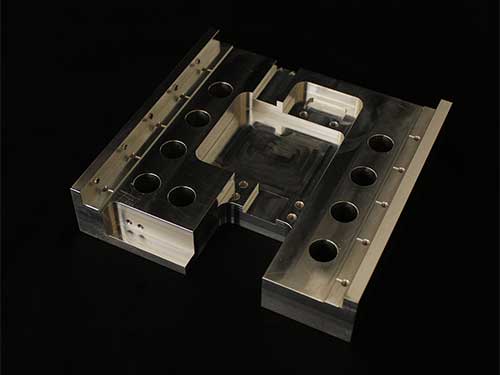

Cradle Base

Alpine Precision CNC machined this 6061-T6 aluminum traverser plate. The part is milled to exceedingly tight GD&T’s with a high cosmetic specification. This part is produced in mid-volume production for one of our SEM/FIB semiconductor client.

The finished part measured 5.584″ long, 5.454″ wide and 1.221″ thick. Multiple flatness and perpendicularity GD&T’s machined to .0002” and true positions of .002”. Our delivery/turnaround time was three to four weeks and we now produced ~50 units per year for this client. For more information on the CNC machining we provided on this traverser plate, please see the chart below or contact us directly.

Project Highlights

Housing for Z drive transmission gears.

Primary: CNC Milling

- Drilling

- Counterbore

- Tapping

- Reaming

- Heat Treatment

Length: 5.584″

Width: 5.454″

Height: 1.221″

.0002

6061-T6 Aluminum

None

Mechanical inspection using Zeiss CMM

SEM/FIB, Semiconductor

50/year

3-4 weeks

Massachusetts

Cradle Base, Traverser plate